3D laser tube cutting

State-of-the-art 3D laser cutting technologies

With state-of-the-art 3D laser cutting technologies, we can eliminate several costly operations in one go, including drilling, sawing, milling, counterboring and punching. With our new 3D Laser Tube cutting Machines the entire process is performed in one go, saving customers up to more than 50% of the usual amount of time required for the assignment. With this in mind, we feel confident in saying that this is the future of our industry!

3D laser cutting produces exceptionally homogenous and precise results which facilitate post-processing flows and, in turn, significant savings in our own manufacturing. We offer 3D laser cutting machines for a large variety of materials, using the latest 3D laser cutting technology. Whether a task calls for counterboring or an assembly kit with a framework in square workpieces or tubes, 3D laser cutting is the best choice. The end result is always beautiful workpieces with precise corners and edges.

2.5D Tube cutting Versus 3D Tube cutting

Advantages of real 3D tube cutting

High-quality bevel cuts of up to +-135 degrees

With high-quality bevel cuts, you can expand your range of parts in mild steel, stainless steel, and aluminum. You also benefit from completely new design options. This allows you to avoid subsequent processes such as preparing welding edges or chamfering

Diagonal cutting – one function that changes everything

Our 3D tube laser cutting machines' ability to pivot their cutting head in an additional, fifth axis, even up to +-135°, represents the solution to one of the greatest problems in modern profile machining. When the laser beam always meets the tube being machined at precisely 90°, this results in an elliptical cutting edge with as reesult none close fitting assemblies. Now the option to pivot the tube laser cutting head, together with the feed axis, makes it possible to achieve a fully diagonal cut and to make perfect fittings in your constructions.

3D tube laser cutting technology replaces a number of traditional methods at one time.

- Replace a band saw and a drill, allows milling or chamfer edges.

- Reducing production time and lower manufacturing costs.

- Extremely flexibility, precision and top quality cutting, as well as wide field of application.

- Open profiles and flat steel can be processed, as well as profiles of various shapes, with diameter till 220 mm (opt 320 mm)

- Automated parameter settings and tube feeding speed.

- 3D laserhead from Raytools or WSX depend model

- more than 50% time reduction for average parts

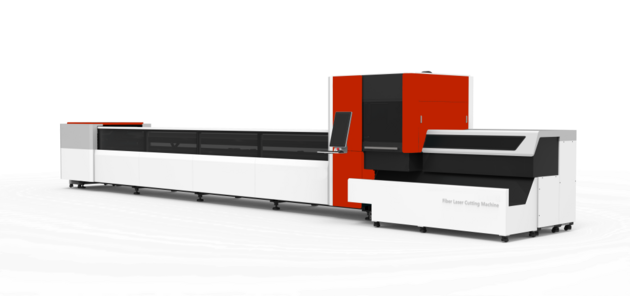

Lasermach LFT 3th Generation 3D Tube cutting Machines

Tube Cutting with a perfect Fit

LFTIII-3D-E Serie

Entry Level Machine for small and mediem series + Prototypes

LFTIII-3D-HD Serie

Heavy Duty Series

LFTIII-3D-HSP Serie

High Speed - High Precision Series

LFTIII-3D-ZERO Serie

ZERO LOSSES - 3 chuck tube laser

Lasermach LFT 3th Generation 3D Tube cutting

Our new standard of laser tube cutting

| Lasermach LFT 3th Generation Tube cutting | LFTIII-3D-E Serie | LFTIII-3D-HD Serie | LFTIII-3D-HSP Serie | LFTIII-3D-ZERO Serie |

|---|---|---|---|---|

| Entry - Economical Series | Heavy-Duty Series | High Speed& Precision Series | ZERO LOSSES - 3 chuck tube laser | |

| tube cross-sectional shape | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel | Round tube, square tube, rectangular tube channel steel, angle steel |

| Basic parameter | ||||

| tube size range | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm | Round tube Φ10-Φ220mm |

| optional Φ350mm | optional Φ320mm | optional Φ320mm | ||

| Square tube □10 - □150mm | Square tube □10 - □150mm | Square tube □10 - □150mm | Square tube □10 - □150mm | |

| optional □240mm | optional □220mm | optional □220mm | ||

| One edge max length | 170mm | 180 / opt 280mm | 170 / opt 270mm | 170 / opt 270mm |

| Requirements for tubes minimum wall thickness | 0.3mm | 0.3mm | 0.3mm | 0.3mm |

| Maximum machinable tube length | 6200mm (opt 8200mm) | 6200mm (opt 8200mm) | 6500mm (opt 9200mm) | 6500mm (opt 9200mm) |

| maximum weight in chuck | 150kg | 190kg/ opt 450kg | 170kg/ opt 400kg | 170kg/ opt 400kg |

| Maximum tube weight | max 160Kg/m | max 220Kg/m -300kg(Φ350mm) | max 220Kg/m -300kg(Φ320mm) | max 220Kg/m -300kg(Φ320mm) |

| Maximum blanking length | 3000mm | 3000mm | 3000mm | 3000mm |

| Shortest remaining material | 40mm | 40mm | 40mm | 40mm |

| Dimensions LxBxH | 9500mm x 2280mm x 2450mm | 9700mm x 2280mm x 2560mm | 10500mm×3120mm×2350mm | 10500mm×3120mm×2350mm |

| Machine weight | 6450 kg | 7600kg- 14800kg with ATC | 8600kg - 13400 with ATC | 8400kg - 12800 with ATC |

| Positioning accuracy | 0,02mm | 0.03mm | 0.025mm | 0.025mm |

| Repositioning accuracy | 0,01mm | 0.02mm | 0.016mm | 0.016mm |

| Max. Chuck rotating speed | 170r/min | 80r/min | 80r/min | |

| Operation parameter | ||||

| axis maximum speed | 120m/min | 100m/min | 100m/min | |

| X maximum acceleration | 1.5G | 1.5G | 1.5G | 1.5G |

| Y maximum acceleration | 1G | 1G | 1G | 1G |

| Φ20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| Processing precision | ||||

| □20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| □20mm square position size difference | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| Laser source | Raycus/MAX/IPG | Raycus/MAX/IPG | Raycus/MAX/IPG | Raycus/MAX/IPG |

| laser head | Han's Raytools/opt Precitec, WSX,.. | Han's, Raytools/opt Precitec, WSX,.. | Han's , Raytools/opt Precitec, WSX,.. | Han's , Raytools/opt Precitec, WSX,.. |

| Automatic focusing function of laser head | incl | incl | incl | incl |

| Optical system | ||||

| Multi-stage perforation Technology | incl | incl | incl | incl |

| smooth cutting technology | incl | incl | incl | incl |

| Anti-slag protection function of double cyclones | incl | incl | incl | incl |

FIBERSAW High speed laser cutting Machines for Tubes

New Website under construction

NEW Website for high speed 3D tube cutting with light!

We are working hard to bring you a new website special build-up for tube and pipe cutting.

Please have some patience we are working hard on the new design

High Speed Cut-to-Length Tube Cutting System - CNC Tube Cutoff Machine - CNC Tube Cutting Machine with Automatic Feed - Fully automatic metal pipe and tube cutting machine with auto loading - CNC Tube Cutting Machines - CNC Straight Tube Cut-off Machine - A Tube Processing System Designed for Automatic Feed & Cut - high Speed Tube Cut-Off Machine - High Speed Cut-to-Length Tube Cutting System - High Speed Cut-to-Length Tube laser Cutting System - CNC laser Tube Cutoff Machine - CNC laser Tube Cutting Machine with Automatic Feed - Fully automatic metal pipe and tube laser cutting machine with auto loading - CNC laser Tube Cutting Machines - CNC laser Straight Tube Cut-off Machine - A laser Tube Processing System Designed for Automatic Feed & Cut -- high Speed laser Tube Cut-Off Machine - High Speed laser Cut-to-Length Tube Cutting System