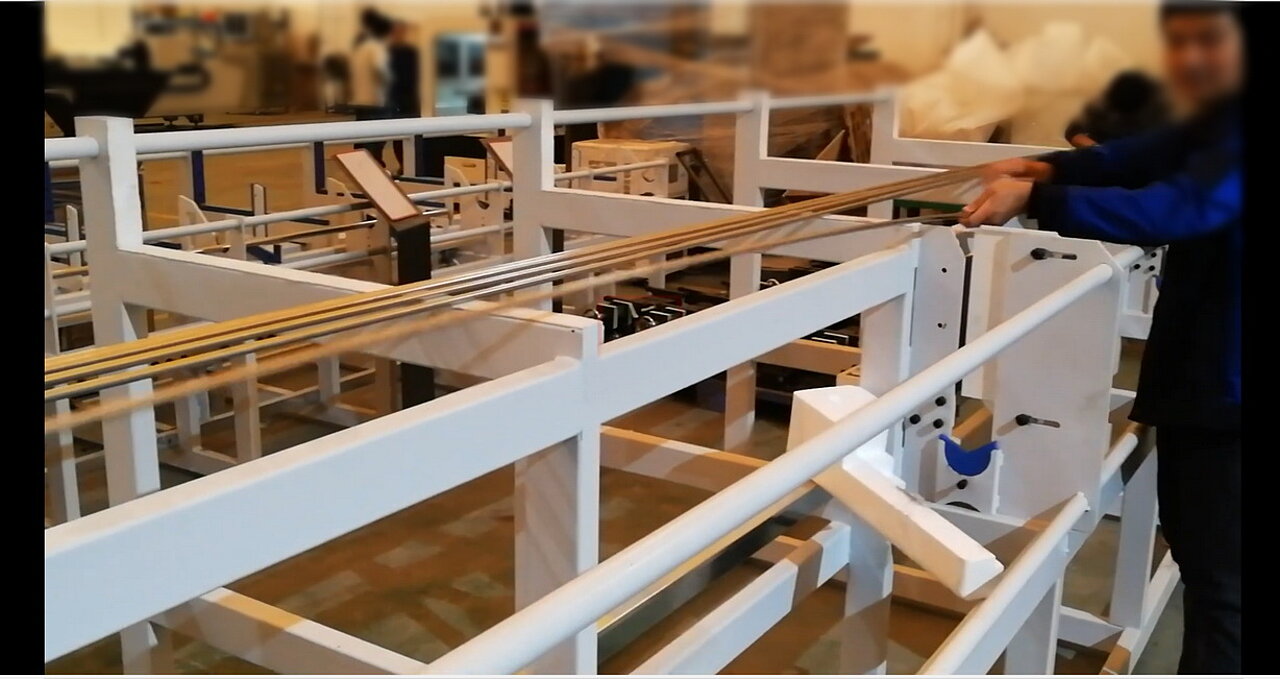

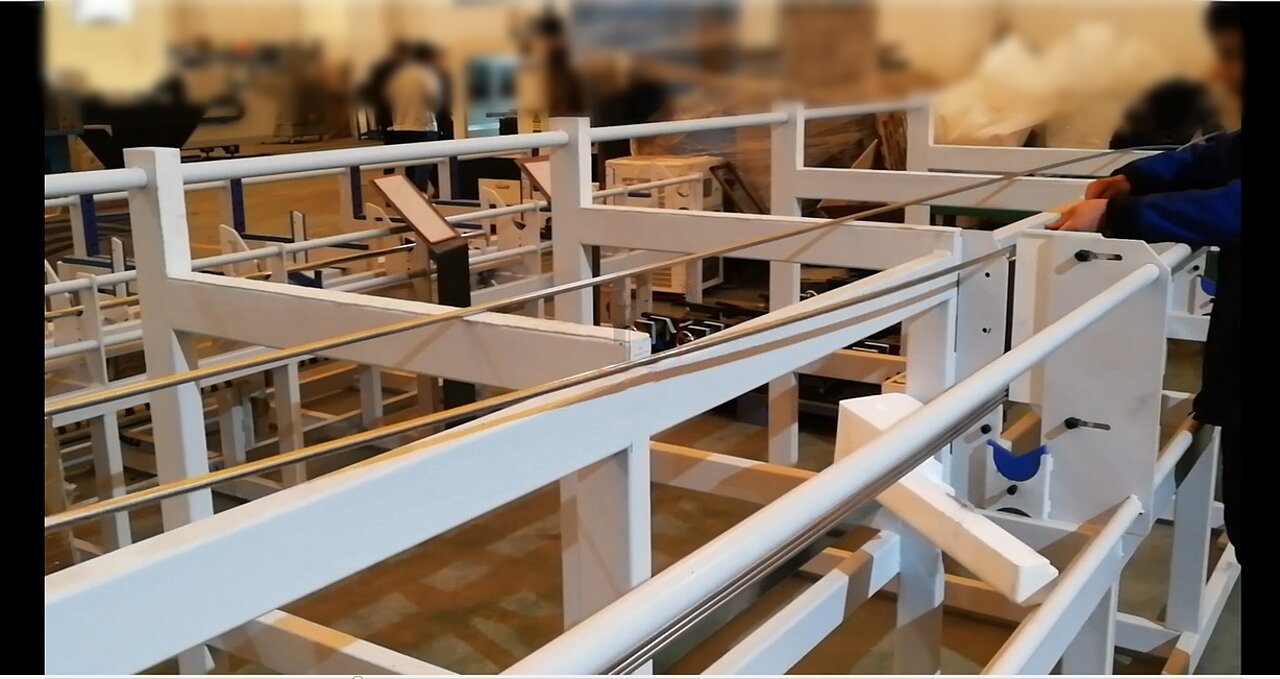

Side-gravity feeder for thin tubes

Tube feeder with good solution for difficult to allign thin tubes.

When cutting smaller tubes of 6 m long we have the experience that the big full automatic bunker loader get a lot of time stocked with tubes not aligning well as they bent or roll during transport, or that the tubes are not straight. Therefor we do not recommend the bunker loader for tubes smaller then 10-12mm diameter. The loader we specially developed for this thin tubes and we recommend for this is with vertical stock of bars of 300 mm high, this means 50 tubes of 6 mm with 6 meter length can be loaded and are ready to run unmanned. The tubes are dropped in bigger quantity on a platform on top of the loader and then manual sorted into the 300 mm bunker, which releases the tubes one by one!

Thin tubes dropped in the backside bunker by bundle in big volume, can be manual sorted and alligned and dropped into the vertical gravity feeder, where the tubes can not roll over each other. The vertical gravity bunker can handle 300 mm of tubes of 3000 or 6000 mm. On top of the loader can be placed a full bundle of tubes, but they need to be sorted manually and loaded by hand into the buffer of 300 mm.

When the tubes are bigger in diameter we can use the bunker easily as the tubes has no tendency to roll over each other and not to be aligned anymore. Bigger than 15/20 mm never gives this problem.

See added pictures for an installation of 8 mm tubes where even after putting the tubes in the vertical loader of 300mm, the ends of the tubes are difficult to keep aligned and straight (mostly due transport bending), but our machine can handle like this. We have many installations for 8 mm tubes like this installed worldwide.